Cold Store Panels

Cold Store Panels

EIP’s Cold Store Panels (CSP) are designed for temperature-controlled environments, suitable for internal walls, ceilings, partitions, and external roofs. The panels feature excellent insulation and durability, integrated waterproofing, and a design that allows for quick and efficient installation. This guarantees reliable performance across diverse cold storage applications.

Thermal Performance & Weight

| Core Thickness (mm) | 55 | 80 | 100 | 120 | 140 | 150 | 170 | 200 |

| Weight (kg/m2)1 | 10.4 | 11.4 | 12.2 | 13 | 13.8 | 14.2 | 15 | 16.2 |

| U-value – PIR (W/m²K)2 | 0.38 | 0.26 | 0.21 | 0.17 | 0.15 | 0.14 | 0.12 | 0.1 |

1Based on 0.50mm thick outer facers

2As per foam laboratory values

Note: Consult EIP’s technical team for updated values using different foam systems.

CSP Joint System

With a double tongue-and-groove joint, these panels interlock together perfectly, delivering airtight, fire-rated performance you can trust.

This system eliminates thermal bridging and provides superior insulation integrity. The extended steel edges within the joint add structural strength and delay flame penetration, enhancing fire protection and overall durability.

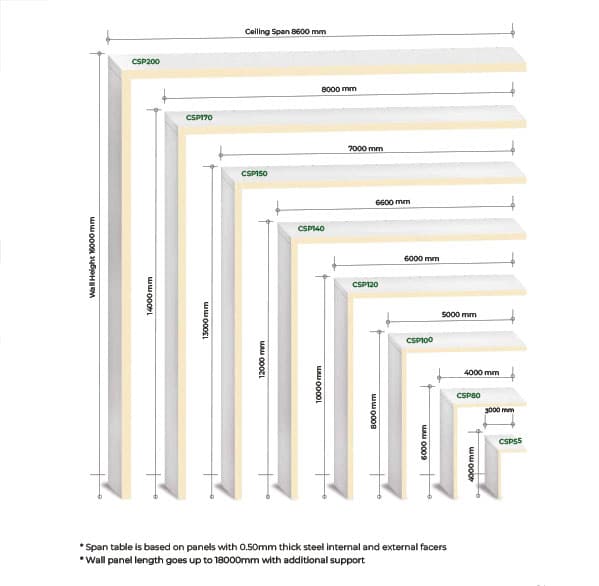

Wall and Ceiling Span Guide

EIP’s Cold Store Panels (CSP) are available in lengths ranging from 2000 mm to 18000 mm.

The span table is based on panels with the standard 0.50 mm steel thickness for both internal and external facers.

When used as self-standing partition panels, the span guide indicates the maximum CSP panel lengths achievable for different thicknesses.

System Width: 1110 mm (effective coverage width)

Profile Options: Low Rib, Flat, Groove, Microline, and Microwave

Heat Transmission Table

| Panel Thickness (mm) | 55 | 80 | 100 | 120 | 140 | 150 | 170 | 200 |

| Temperature Differential (TD) | ||||||||

| 10 ºC | 3.78 | 2.6 | 2.08 | 1.73 | 1.49 | 1.39 | 1.22 | 1.04 |

| 15 ºC | 5.67 | 3.9 | 3.12 | 2.6 | 2.23 | 2.08 | 1.84 | 1.56 |

| 20 ºC | 7.56 | 5.2 | 4.16 | 3.47 | 2.97 | 2.77 | 2.45 | 2.08 |

| 25 ºC | 9.45 | 6.5 | 5.2 | 4.33 | 3.71 | 3.47 | 3.06 | 2.6 |

| 30 ºC | 11.35 | 7.8 | 6.24 | 5.2 | 4.46 | 4.16 | 3.67 | 3.12 |

| 35 ºC | 13.24 | 9.1 | 7.28 | 6.07 | 5.2 | 4.85 | 4.28 | 3.64 |

| 40 ºC | 15.13 | 10.4 | 8.32 | 6.93 | 5.94 | 5.55 | 4.89 | 4.16 |

| 45 ºC | 17.02 | 11.7 | 9.36 | 7.8 | 6.69 | 6.24 | 5.51 | 4.68 |

| 50 ºC | 18.91 | 13 | 10.4 | 8.67 | 7.43 | 6.93 | 6.12 | 5.2 |

| 55 ºC | 20.8 | 14.3 | 11.44 | 9.53 | 8.17 | 7.63 | 6.73 | 5.72 |

| 60 ºC | 22.69 | 15.6 | 12.48 | 10.4 | 8.91 | 8.32 | 7.34 | 6.24 |

| 65 ºC | 24.58 | 16.9 | 13.52 | 11.27 | 9.66 | 9.01 | 7.95 | 6.76 |

| 70 ºC | 26.47 | 18.2 | 14.56 | 12.13 | 10.4 | 9.71 | 8.56 | 7.28 |

| 75 ºC | 28.36 | 19.5 | 15.6 | 13 | 11.14 | 10.4 | 9.18 | 7.8 |

| 80 ºC | 30.25 | 20.8 | 16.64 | 13.87 | 11.89 | 11.09 | 9.79 | 8.32 |

| 85 ºC | 32.15 | 22.1 | 17.68 | 14.73 | 12.63 | 11.79 | 10.4 | 8.84 |

Thermal conductivity factor for PIR foam λ= 0.0208 W/mK

Minimum value for heat gain in a coldstore = 10 W/m2

TD = Temperature difference between inside and outside of coldstore.