Roof & Wall Panels

Roof & Wall Panels

EIP’s Roof and Wall Panels deliver superior insulation, strength, and flexibility. Designed for warehouses, factories, cold stores, and modern industrial facilities, our panels are engineered to perform in the toughest climates.

EIP panels combine modern aesthetics with technical performance. Featuring multiple profiles and thicknesses, our range suits industrial, commercial, and architectural applications, ensuring energy savings, fire resistance, and long service life.

Products

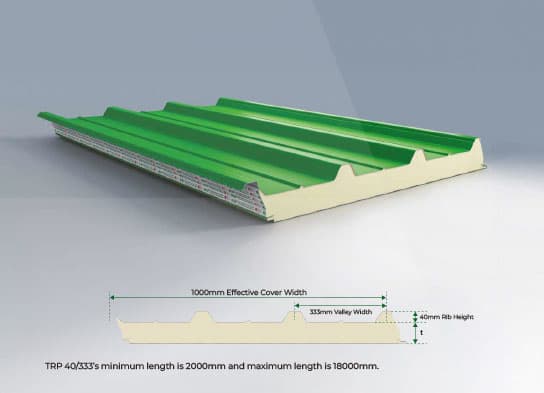

TRP: Trapezoid Roof Panel 40/333

The TRP 40/333 is a trapezoidal roof panel, through-fixed on the side-lap joints. The name ‘40/333’ indicates the rib height (40mm) and valley width (333mm).

The 40mm-high ribs provide superior strength and water resistance, withstanding extreme weather while maintaining air-tight performance.

This versatile cladding solution is suitable for all buildings with roof slopes as low as 2.85o (5.0%)1. For specific cases, EIP’s technical team can advise on the ideal slope based on building length.

All EIP TRP panels can be installed as roof or wall fixtures.

1 Contact EIP’s technical team for assistance with selecting the correct design for your required slope

| Thermal Performance & Weight | ||||||

| Core Thickness (mm) | 40 | 50 | 60 | 75 | 100 | 150 |

| Weight – Steel (kg/m²)2 | 10.30 | 10.70 | 11.10 | 11.70 | 12.70 | 14.70 |

| Weight – Aluminum (kg/m²)3 | 5.40 | 5.80 | 6.20 | 6.80 | 7.80 | 9.80 |

| U-value – PIR (W/m²K)4 | 0.43 | 0.36 | 0.31 | 0.25 | 0.19 | 0.13 |

| U-value – PUR (W/m²K)4 | 0.47 | 0.40 | 0.34 | 0.28 | 0.21 | 0.14 |

2 Based on 0.50mm thick outer facers

3 Based on 0.70mm thick outer facers

4 As per foam laboratory values

* Consult EIP’s technical team for improved values using different foam systems